Flux: An Introduction to HJ431

Flux is an essential component in the field of welding, as it plays a crucial role in ensuring the quality and strength of the weld joint. One such flux widely used in the industry is HJ431. In this article, we will explore the characteristics and applications of HJ431 flux.

- Composition of HJ431 Flux:

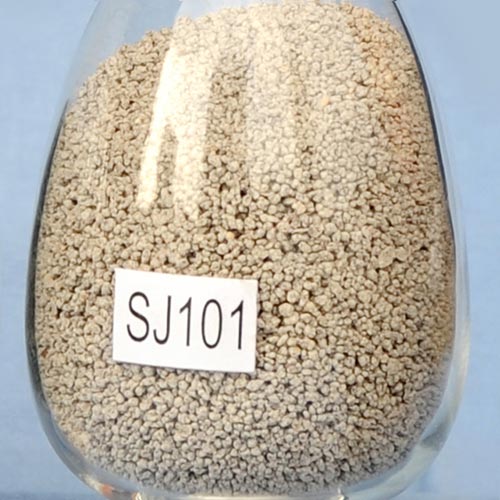

HJ431 flux is primarily composed of a mixture of chemicals, including borax, potassium chloride, and sodium fluoride. These ingredients are carefully blended to create a flux that efficiently removes impurities, promotes the formation of a clean weld joint, and enhances the overall welding process.

- Characteristics of HJ431 Flux:

– High melting point: HJ431 flux has a high melting point, allowing it to withstand the high temperatures generated during welding without losing its effectiveness.

– Good wetting ability: The flux spreads easily on the metal surface, ensuring proper coverage and enabling the removal of oxides and other impurities from the weld.

– Low fume emission: HJ431 flux emits minimal fumes during the welding process, making it a safer option for both the welder and the environment.

– Stable arc: The use of HJ431 flux helps stabilize the welding arc, resulting in improved control and better weld penetration.

- Applications of HJ431 Flux:

HJ431 flux finds its application in various welding processes, including:

– Shielded Metal Arc Welding (SMAW): HJ431 flux is commonly used in SMAW, also known as stick welding, where it helps in the removal of impurities and ensures the formation of a strong weld joint.

– Flux-Cored Arc Welding (FCAW): HJ431 flux is also suitable for FCAW, where it aids in the formation of a clean weld joint, preventing the occurrence of defects such as porosity and slag inclusions.

– Gas Metal Arc Welding (GMAW): HJ431 flux is sometimes used in GMAW, also known as MIG/MAG welding, to enhance the weld quality and improve the overall welding performance.

- Advantages of Using HJ431 Flux:

– Improved weld quality: The use of HJ431 flux helps to create a clean weld joint, free from impurities, resulting in improved weld quality and mechanical properties.

– Reduced post-weld cleaning: HJ431 flux effectively removes oxides and other contaminants during the welding process, minimizing the need for extensive post-weld cleaning.

– Cost-effective: HJ431 flux offers good performance at a reasonable cost, making it a preferred choice for various welding applications.

HJ431 flux, with its unique composition and characteristics, has proven to be an effective flux in the welding industry. Its ability to remove impurities, stabilize the welding arc, and improve weld quality makes it a valuable asset in various welding processes. Whether you are a professional welder or a hobbyist, considering HJ431 flux can help you achieve strong, clean, and high-quality welds.