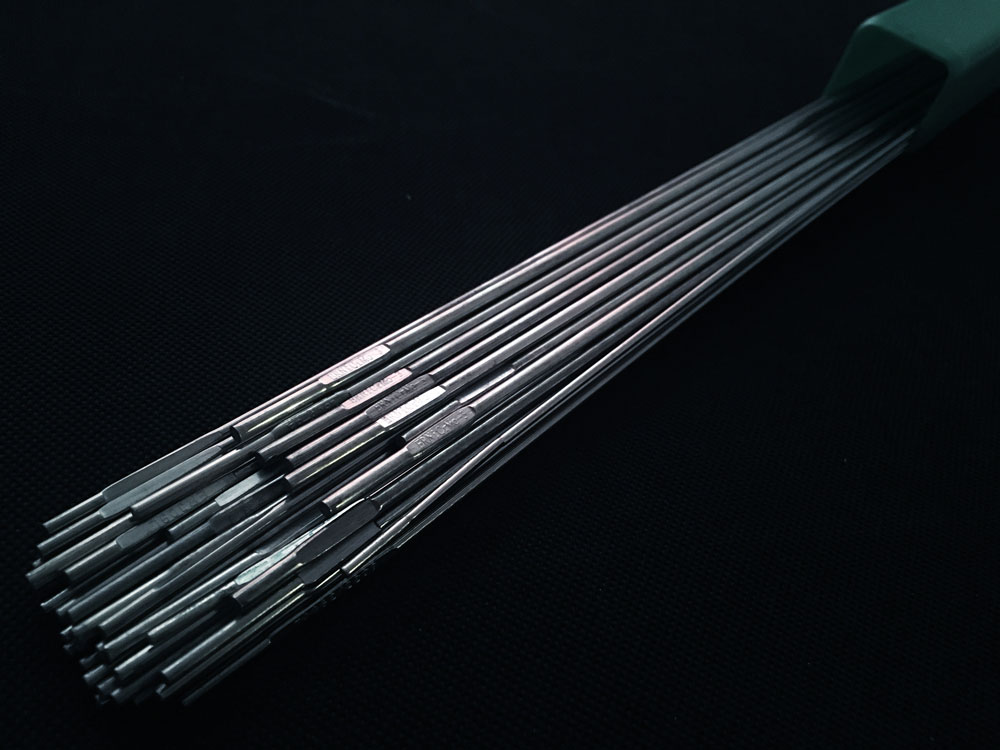

Classification and Applications of Flux-Cored Welding Wires

Flux-cored welding wires are a type of filler metal used in the welding process. They consist of a metal sheath and a flux core, which provides various benefits during the welding process. This article will discuss the classification and applications of flux-cored welding wires.

Flux-cored welding wires can be classified based on several factors, including the type of metal used in the sheath and the type of flux core. The most common types of flux-cored welding wires are:

These wires are used for welding carbon steels and low-alloy steels. They have a carbon steel sheath and a flux core that provides excellent penetration and weld strength. Carbon steel flux-cored welding wires are widely used in construction, shipbuilding, and structural fabrication.

Stainless steel flux-cored welding wires are designed for welding stainless steel and other high-alloy steels. They have a stainless steel sheath and a flux core that helps prevent oxidation and provides good corrosion resistance. These wires are commonly used in the food processing industry, chemical plants, and automotive applications.

Nickel alloy flux-cored welding wires are used for welding nickel-based alloys and dissimilar metals. They have a nickel alloy sheath and a flux core that ensures high-quality welds with excellent mechanical properties. These wires are commonly used in the aerospace industry, power generation, and petrochemical applications.

Applications of Flux-Cored Welding Wires:

Flux-cored welding wires have various applications across different industries. Some of the common applications include:

- Structural Welding:

Flux-cored welding wires are widely used for structural welding in the construction and fabrication industry. They provide high deposition rates, good penetration, and excellent weld strength, making them suitable for joining large structural components.

- Pipeline Welding:

Flux-cored welding wires are commonly used for pipeline welding due to their high welding speed and ability to weld through contaminants such as rust and oil. They provide strong and reliable welds, ensuring the integrity of the pipelines.

- Repair and Maintenance:

Flux-cored welding wires are also used for repair and maintenance applications. They can be used to repair worn-out or damaged components, including machinery parts, equipment, and metal structures.

Flux-cored welding wires are versatile filler metals used in various industries for different welding applications. Their classification based on the type of metal sheath and flux core allows for specific usage in different materials and environments. Understanding the classification and applications of flux-cored welding wires is crucial for selecting the appropriate wire for specific welding needs.